Welcome to our websites!

News

-

The Future of PVC Recycling:Advanced Crushing Systems for B2B Buyers

PVC recycling is evolving rapidly, thanks to advanced crushing systems. These technologies bring precision and efficiency to PVC waste management, making recycling more effective than ever. For B2B recycling equipment buyers, investing in cutting-edge solutions is no longer optional. It’s a smar...Read more -

Case Study:How a German Auto Parts Supplier Reduced Waste by 40% with Our Cutter

Waste reduction plays a critical role in the automotive industry, where efficient resource management directly impacts profitability and sustainability. The global automotive waste management market, valued at approximately USD 4 billion in 2023, is projected to grow to USD 7.5 billion by 2032, ...Read more -

Top 10 Cold Pellet Cutters for Efficient Plastic Processing in 2025

Cold pellet cutters play a vital role in producing high-quality plastic pellets, ensuring precision and consistency. The plastic processing machinery market is projected to grow from $38.71 billion in 2024 to $40.88 billion in 2025, driven by a 5.6% CAGR. Advancements in technology continue to s...Read more -

Top 10 Benefits of Wholesale Purchasing Energy-Saving Granulators for Eco-Friendly Manufacturing

Beckett PowerLight and Forney Q87 are recognized as top-tier solutions in the field of Oil-Fired Pules Igniter and Gas-Fired/Oil-Fired Pules Igniter. These devices significantly boost factory productivity by offering outstanding energy efficiency and unparalleled reliability. With their advanced...Read more -

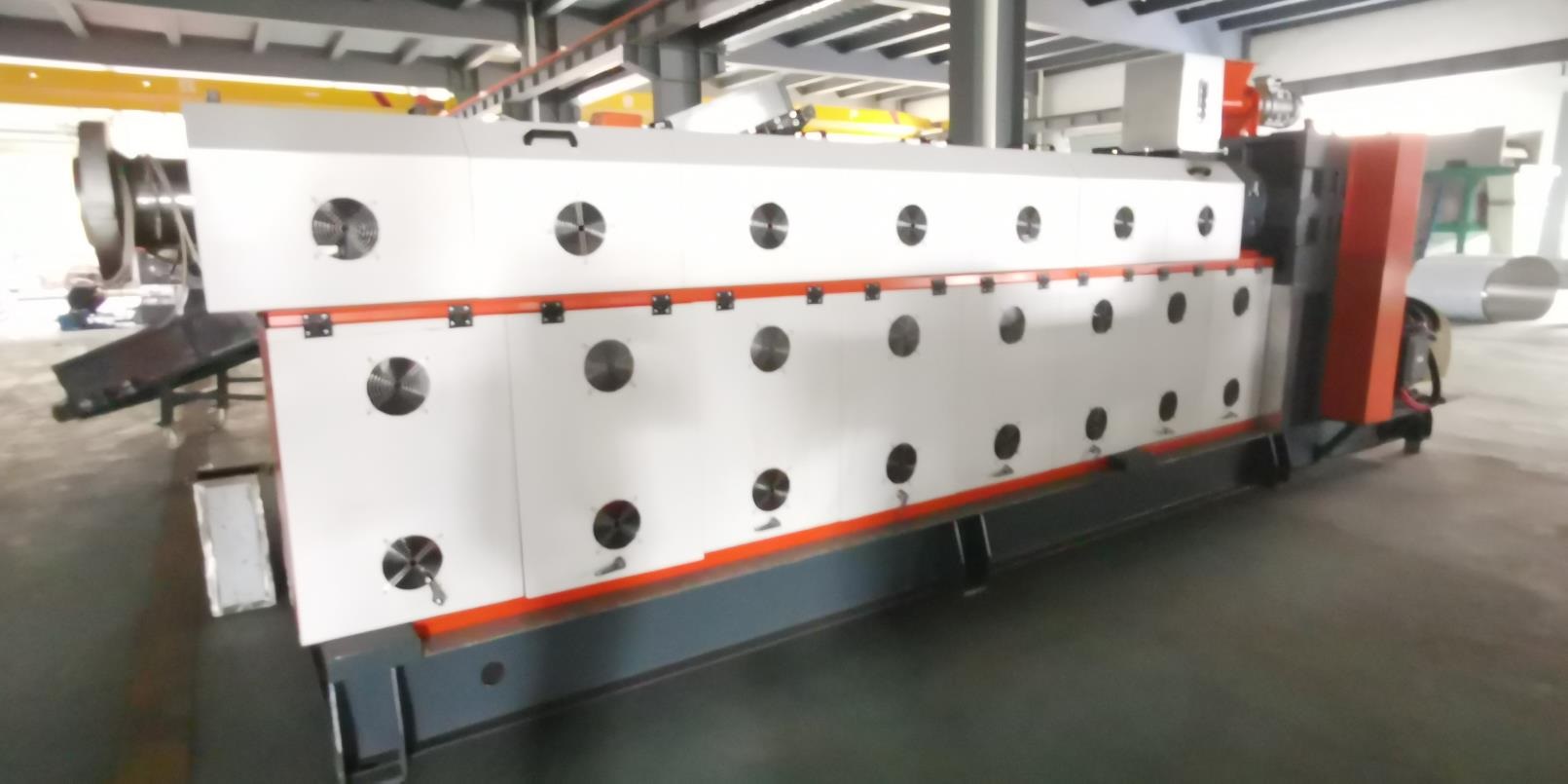

Plastic granulator recycling granulator waste plastic recycling machine

The U.S. recycling industry faces significant inefficiencies that hinder its progress. For instance: Contamination costs material recovery facilities over $300 million annually. Only 32.1% of waste is recycled or composted, leaving vast potential untapped. Recycling logistics costs can soar to ...Read more -

Top 10 Plastic Recycling Machines for Woven Bags and Films in 2025

Recycling woven bags and films is essential for safeguarding our planet. In 2021 alone, over 264 million pounds of these materials were recycled, marking a 7.9% increase from the previous year! The film woven bag waste plastic recycling machine whole production line streamlines and enhances this...Read more -

Your Guide to Choosing the Best Battery Gas Pulse Igniter

Choosing the ideal battery Gas Pules Igniter is not only about convenience but also about ensuring safety and optimal performance. You need a product that is dependable, user-friendly, and perfectly suited to your appliances. Key features such as extended battery life and proper certifications ar...Read more -

Tips to Enhance Plastic Bottle Recycling Efficiency

Recycling plastic bottles efficiently isn’t just about reducing waste—it’s about creating a cleaner planet and saving resources. Did you know Europe recycles 52% of its plastic bottles, while the U.S. lags behind at just 4.4%? Region Recycling Rate Year U.S. 4.4% 2018 U.S. (PET) 31% 201...Read more -

Take you into the control system of plastic pelletizing machine detailed explanation

The control system of plastic pelletizing machine includes heating system, cooling system and process parameter measuring system, which mainly consists of electrical appliances, instruments and actuators (i.e. control panel and operation desk). Its main functions are: to...Read more -

Plastic bottle pelletizing machine detailed explanation

The main machine of plastic pelletizing machine is extruder, which consists of extrusion system, transmission system and heating and cooling system. Vigorously develop renewable resources, turning waste into treasure. 1. extrusion system extrusion system including hopper...Read more -

Plastic bottle granulator problems troubleshooting, you know how much

1. The screw runs normally, but does not discharge material Causes: hopper feeding is not continuous; feed port is blocked by foreign objects or produce "bridge"; screw groove into the metal hard objects blocking the screw groove, not normal feeding. Treatment: increase ...Read more -

Energy-saving features of plastic pelletizing machine

Energy saving on plastic pelletizing machine can be divided into two parts: one is the power part, one is the heating part. Power part of the energy saving: most of the use of inverters, energy saving by saving the remaining energy consumption of the motor, for example, ...Read more