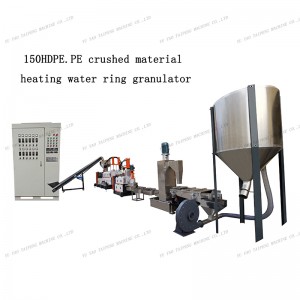

Plastic granulator recycling granulator waste plastic recycling machine

Type: Granulating Production Line

Screw Design: Single 125, 28:1, 100rpm - 150rpm

Voltage: 380V/440V/415V/customized

Dimension(L*W*H): 3400X1900X2600

Power (kW): 37

Weight: 2000

Warranty: 1 Year

Showroom Location: Canada, United States, France, Germany, Viet Nam, Philippines, Saudi Arabia, Indonesia, Pakistan, Mexico, Russia, Spain, Thailand, Morocco, Argentina, South Korea, Chile, UAE, Colombia, Romania, Bangladesh, South Africa, Kazakhstan, Kyrgyzstan, Nigeria, Uzbekistan, Japan, Malaysia, Australia

Applicable Industries: Manufacturing Plant, Energy & Mining, Other

Extruder: Single Screw Plastic Extruder

Pelletizer: Single screw granulator

Plastic recycling machine: Single screw recovery machine

Granulator: Waste plastic single screw pelleting machine

pp pe bas: pp pp abs waste plastic single screw pelleting machine

Greenhouse membrane material recycling machine: Greenhouse film material single screw recovery machine

Waste material crushing and pelleting machine: Waste material crushing treatment single screw pelleting machine

Granulator: Return pelleting machine

Crushing of hard plastics: Hard plastic grinding and regenerating granulator

Crushing of soft plastics: Soft plastic crushing and regenerating granulator

Marketing Type: New Product 2022

Core Components: Bearing, Gearbox, Motor

Place of Origin: China, Zhejiang

Brand Name: Taipeng machinery

The recycled materials are automatically transported to the mixing port through the conveyor belt, and the heating screw is used to stir, heat and melt the materials, so that they are ejected in a strip shape through the die head, and then cooled by the water tank, cut into granular objects and packaged. The whole machine has a compact and reasonable structure, which integrates crushing, automatic feeding, mixing, forced feeding and granulation.

1. The motor is large, the feeding capacity is large, the screw is larger than that of the same model in the same industry, and the discharge hole is more than that of the same industry. The gearbox is larger than its peers.

2. Self-produced recycled materials can directly foam pearl cotton, reduce production costs and improve production efficiency.

3. It is characterized by high output, simple operation, stable performance and low energy consumption.

4. Recycling waste, saving raw materials, environmental protection production, energy conservation and emission reduction.