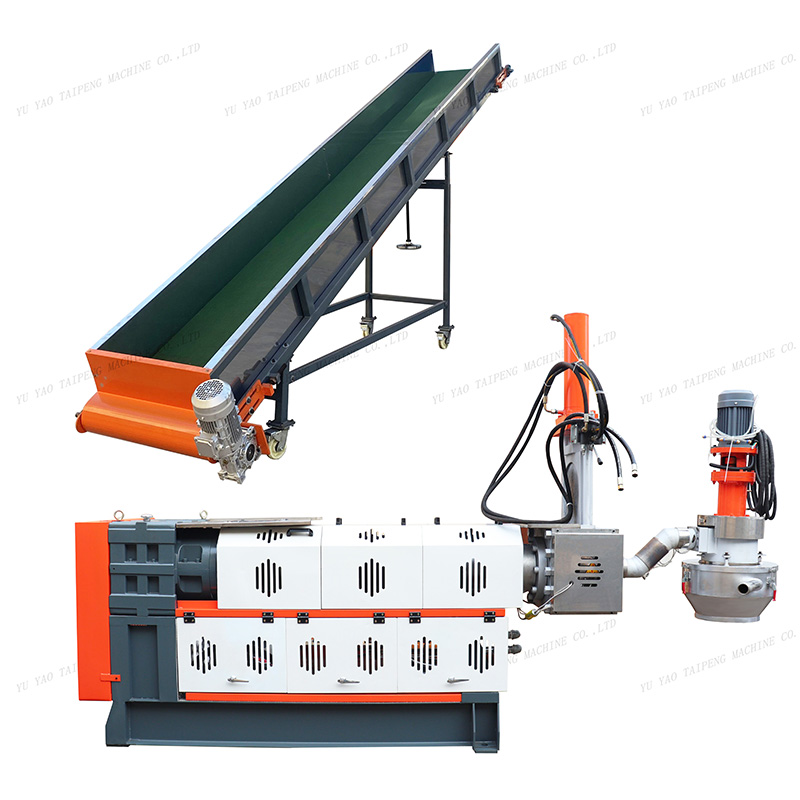

PP HDPE LDPE film woven bag waste plastic recycling machine whole prodution line

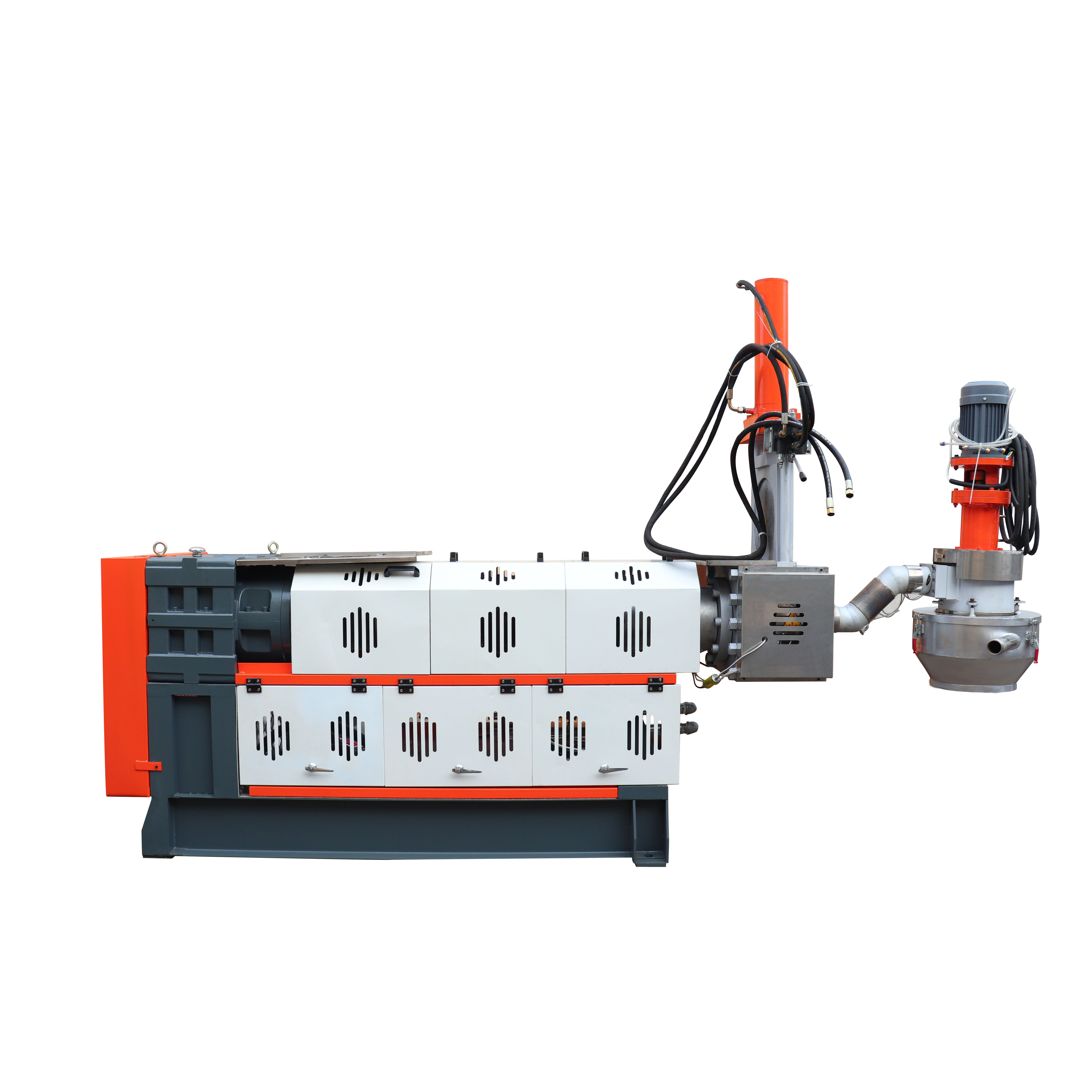

Type 150 host machine

This machine with 90KW motor, type 280 gearbox hard tooth, 38CrMoAI nitriding screw with 4000mm length,Type 850 agglomerator with 75KW motor.

Type 150 secondary machine

This machine with 37KW motor, type 200 gearbox hard tooth,38CrMoAI nitriding screw with 1500mm length,Hydraulic up and down double grommets for screen changing without stopping 300mm*300mm round hole.

1000kg cacpcity storage

One hig voltage fan 2.2KW,One 1000kg cacpcity storage.

The main parameters of type 150 dry film material with water granulator LLDPE HDPE LDPE film woven bag waste plastic recycling production granulated line:

| Model | Power(kw) | Output(kg/h) | Length(m) | Gearbox Hard |

| Type 180 | 132/55 | 800-900 | 15 | 375/250 |

| Type 160 | 110/45 | 500-600 | 14 | 315/225 |

| Type 150 | 90/37 | 450-500 | 14 | 280/200 |

| Type 130 | 55/37 | 280-300 | 13 | 225/200 |

Plastic Processed: HDPE, HDPE/PP, PE/PP, Lldpe, PP, LDPE, PC

Condition: New

Output (kg/h): 500 - 600 kg/h

Video outgoing-inspection: Provided

Machinery Test Report: Provided

Warranty of core components: 1 Year

Core Components: PLC, Engine, Bearing, Gearbox, Motor, Pressure vessel, Gear, Pump

Place of Origin: Zhejiang, China

Brand Name: TP

Type: Granulating Production Line

Screw Design: Single

Voltage: Customized, Customized

Dimension(L*W*H): 20*5*3m

Power (kW): 400~500

Weight: 21

Warranty: 1 Year

Showroom Location: Japan

Applicable Industries: Manufacturing Plant, Farms, Home Use, Energy & Mining, Advertising Company, Other

Screw Speed (rpm): 75 - 85 rpm

After Warranty Service: Field maintenance and repair service

Gearbox: Hard-teeth

Mould: Hydraulic filter changer

Color: Customized

Heating method: Cast-Al heating

Capacity: 30 sets/ month

Power: customized

Certification: ISO

Screw L/D Ratio: 27:1

30 Set/Sets per Month

Packaging Details: well sold PP HDPE LDPE ABS PS PC PA PVC EPS film woven bag waste plastic recycling machine manufacturer

Wooden pallets with the film covered, and customized according to the clients.

Port: Ningbo, Shanghai,Zhangjiagang

Lead time:

|

Quantity(sets) |

1 - 1 |

2 - 5 |

6 - 10 |

>10 |

|

Lead time (days) |

20 |

30 |

50 |

To be negotiated |

1. Q: How to contact you if I am interested with your machine?

A: You can contact me via Alibaba, i will reply you ASAP. Or you can send me a mail to my mailbox: taipengjixie@163.com

2. Q: If I need the machine urgently, can you send to me on time?

A: In our warehouse, we have enough space to store everything from large spare parts to smaller machines. In a very short amount of time, we can put the machine together, test it, and ship it to you.

3. Q: What can you help if i can not assemble and operate your machine in my own factory ?

A: Our exceptional service is just as important to us as the caliber of the equipment. In the beginning, we can provide video and camera teaching assistance. If this is unable to resolve your issue, we will send qualified engineers to deal with it directly with you.

4. Q: If my machine is unfortunately broken within one year, what can you promise?

A: This kind of circumstance is unusual for us most of the time. But if it does occur, parts and repairs are only free if they are done during the guarantee period and are not the result of improper use.

5.Q: How can I believe your factory and machines?

A: We have spent more than ten years concentrating on this area, and we constantly grow and learn. We have customers all around the world because to our high-quality equipment and friendly service. Additionally, if it is convenient for you, you are welcome to visit our factory before placing an order.

The professional technical service is promised.

1, Free spares support.

2, Free operator training.

3,Video&Camera online teaching and problem solving.

4,Technical person assembling and testing in your factory.

5,Discussing with the clients for the other solutions of the puzzles need to be served.

Supporting equipment I: crusher

There are many different kinds of crushers for plastic products, including impact crushers and compression crushers appropriate for breaking brittle plastic items. Shear crushers can also be used to crush different kinds of plastic products. The base, crushing chamber, feeding hopper, sieve plate, transmission mechanism, rotating knife, and fixed knife are the components of the commonly used shear crusher.

The shear plastic crusher operates in a very straightforward manner. From the feeding hopper, waste plastic is sent to the crushing chamber where it is cut when it passes through the high-speed rotating cutter and then discharged through the perforated sieve plate. The shear knife, which has a rotating blade and a fixed blade, is powered by an electric motor.

Auxiliary equipment II: cleaning machine

After the waste plastic is loaded into the water tank and turned, stirred, and washed by two rotating mixing blades, the washing machine's job is to remove the dirt and sediment from the plastic. The plastic fragments are then lifted out of the water by the lifting device and taken to the dehydration process.