PP PE ABS PS PC PA 300kg/h High Capacity New Technology Plastic Recycling Machine

Plastic Processed: HDPE, HDPE/PP, PE/PP, Lldpe, Polystyrene, ABS/PP, PP, LDPE, ABS

Condition: New

Output (kg/h): 300-350 kg/h

Video outgoing-inspection: Provided

Machinery Test Report: Provided

Warranty of core components: 1 Year

Core Components: Gearbox, Motor

Place of Origin: Zhejiang, China

Brand Name: TP

Type: Granulating Production Line

Screw Design: Single

Voltage: Customized, Customized

Dimension(L*W*H): 4300*1200*1200mm*

1900*710*400mm

Power (kW): 37+15KW

Weight: 4

Warranty: 1 Year

Showroom Location: Egypt, Turkey, Russia

Applicable Industries: Manufacturing Plant, Farms, Home Use, Energy & Mining

After-sales Service Provided: Free spare parts

Gearbox: Hard-teeth

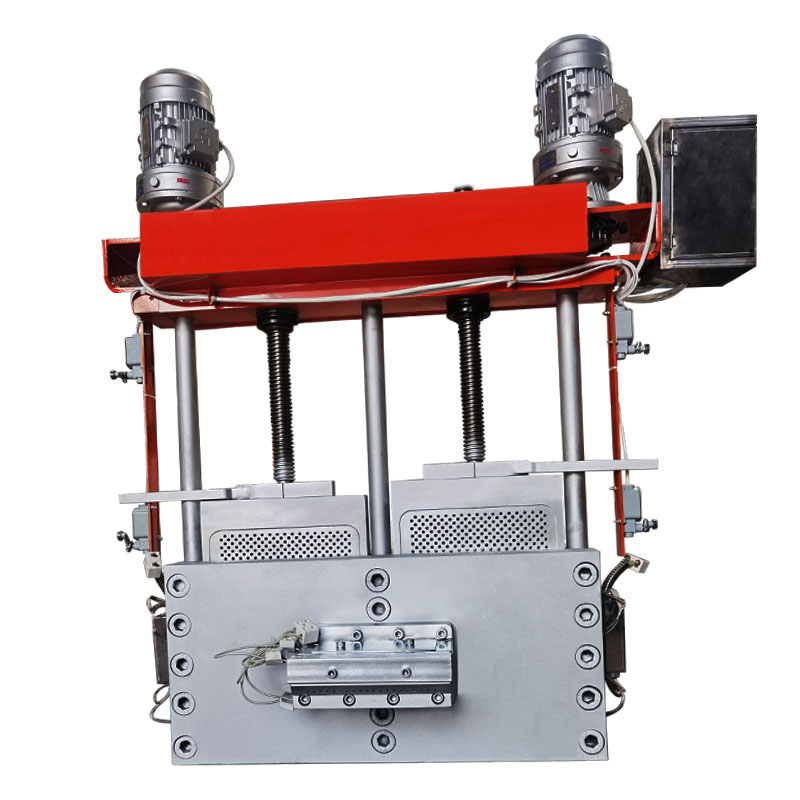

Mould: Hydraulic filter changer

Color: Customized

Heating method: Cast-Al heating

Capacity: 20 sets/ month

Power: Customized

Name: Plastic Granulator Machine

Material: 38CrMoALA

Marketing Type: Ordinary Product

(1) Raise the temperature for roughly forty or fifty minutes before running the machine. Increase the temperature and manually pull the motor triangle belt until it is released; Pull constantly between eight and 10 times in the direction of the regular operating rotation. After around ten minutes, let the machine heat up some more before turning it on because typical production still needs to provide heat;

Depending on the qualities of the plastic, adjust the temperature appropriately.

(2) The temperature of the pelletizer should be steady, not high or low, when it is operating normally. The machine head's temperature must be maintained at or about 200 °C close to the vent opening (refer to material C and material B).

(3) There must be no shortage of supplies and the feeding must be uniform. The machine's feeding speed and the feed rate should be correctly matched. Otherwise, the particle output and quality will suffer.

(4) The main engine must be entirely disconnected before the machine is shut down. Remove the head plug with the included wrench. Before the subsequent usage, separate reheat.